Elevate Your Brand with Premium litho printing

Elevate Your Brand with Premium litho printing

Blog Article

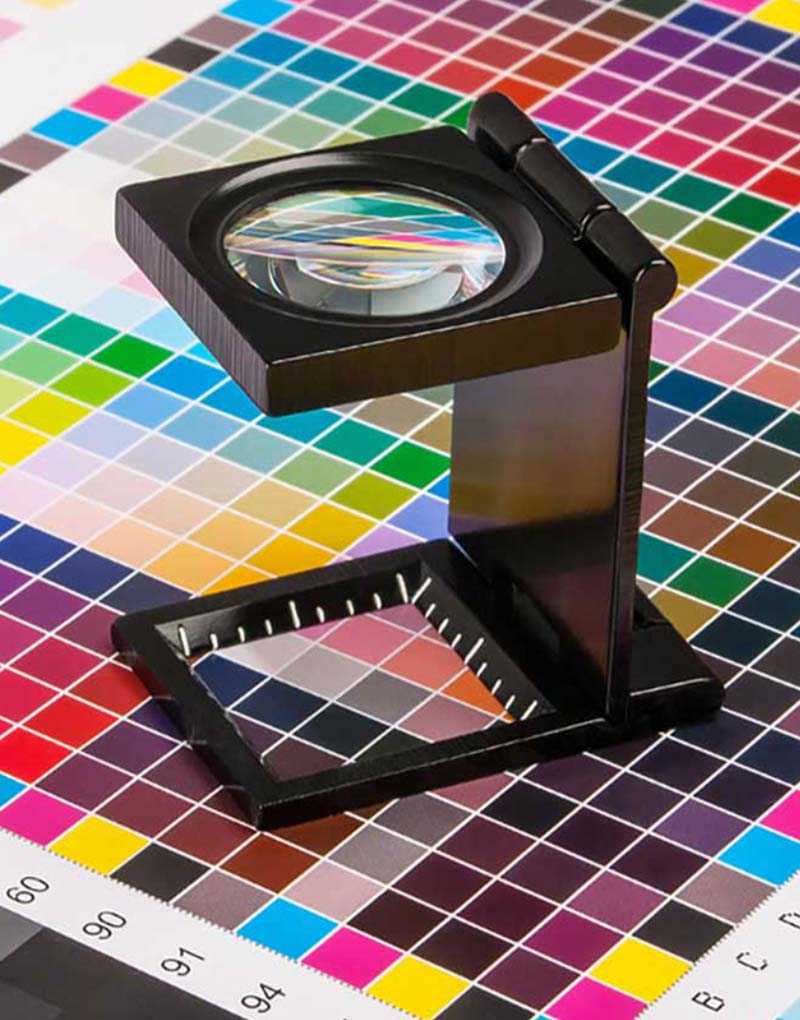

A Comprehensive Guide to Understanding Litho Printing Strategies

The globe of litho printing, a technique stemming from the late 18th century, is an interesting mix of history, art, scientific research and advancement. This extensive guide will untangle the intricacies of this printing technique, from the structure of litho inks to the obstacles encountered in modern-day applications. As we venture into the details of lithography, the value of automation and sustainability in ensuring its future relevance comes to be increasingly clear. Remain with us as we trip into the exciting realm of litho printing.

The Historic Development of Litho Printing

The historic trajectory of litho printing, an essential advancement in the world of interaction, is a captivating story of human resourcefulness. The process developed with the development of the rotating press, which considerably boosted efficiency. Each stage of litho printing's advancement showcases mankind's ruthless quest of efficiency and top quality in aesthetic interaction.

Deciphering the Science Behind Litho Printing Inks

Progressing in the expedition of litho printing methods, the focus currently moves to the science behind litho printing inks. The make-up of these inks, their drying out process, and shade mixing methods form the foundation of this complex art form. Recognizing these aspects is critical to grasping the craft and accomplishing the desired print outcomes.

Composition of Litho Inks

In lithographic printing, the fundamental function of litho inks can not be overstated. The composition of litho inks differs depending on its objective, but typically, they include two primary elements - pigments and automobiles. Pigments, the color-providing aspects, are carefully ground bits put on hold in the lorry, a liquid that carries the pigment onto the printing surface. The lorry is a complicated mix of oils, resins, and solvents, which affect the ink's drying out time, bond, and gloss. In addition, various ingredients are present to boost certain residential or commercial properties like circulation, drying out, and resistance to environmental results. Each component plays a critical part in the final print's top quality, making the accurate formulation of litho inks a detailed science.

Ink Drying Process

From the composition of litho inks, focus transforms to the interesting process of ink drying. 2 key approaches are utilized in litho printing: oxidative drying and absorption. Absorption, on the various other hand, involves the ink seeping right into the paper fibers, which is a quicker procedure but can lead to much less lively shades.

Color Mixing Methods

While the drying out process plays a key duty in litho printing, the science of color mixing strategies holds equal significance. This is a complex process that includes the careful mixing of primaries: cyan, magenta, and yellow, in differing percentages to accomplish a broad array of tones. The addition of black ink, referred to as 'vital', assists in regulating the strength and depth of the colors. The scientific research behind litho printing inks additionally takes into consideration the openness of the ink, which affects just how shades overlay and mix. To attain an effective shade mix, print professionals need to likewise understand the intricacies of ink habits, shade find out this here concept, and the physical buildings of the substratum on which the ink is used.

The Art and Design Aspects in Litho Printing

Litho printing takes a breath life right into art and design via its one-of-a-kind components. Litho printing suits a range of shades, making it possible for musicians to produce lively and dynamic prints. This mix of accuracy and adaptability makes litho printing a favored choice for several musicians and developers.

Modern Applications of Litho Printing Techniques

Litho printing strategies have found extensive usage in the contemporary commercial industry. Its influence and relevance continue to expand with the introduction of brand-new advancements and innovations in the area. This section will certainly explore these contemporary applications and the transformative duty they play in the printing market.

Industrial Litho Printing Uses

Litho printing stays a critical component of the industrial industry. High-volume printing tasks, such as the production of books, newspapers, and packaging, rely on litho printing for its capability to supply premium image quality and cost efficiency. Litho printing likewise supplies a broad color spectrum, superior to that of digital printing.

Developments in Litho Printing

Pressing the limits of standard methods, modern-day developments have fueled a host of innovations in litho printing. These breakthroughs have not just boosted the quality and performance of litho prints yet additionally broadened its application scope. One popular advancement is digital litho printing, which combines the merits of electronic innovation with litho's premium output. This crossbreed model supplies faster arrangement times, lowered waste, and allows on-demand printing. An additional remarkable innovation is the introduction of ecologically friendly inks. These inks, made from veggie or soy-based services, have actually dramatically minimized the market's environmental effect. litho printing. Additionally, the growth of sophisticated plate technology has structured the printing process, causing sharper pictures and boosted color integrity. These advancements underscore the long-lasting relevance of litho printing in the contemporary world.

Checking out the Refine of Litho Printing: Detailed

Challenges and Solutions in Contemporary Litho Printing

Despite the precision and tradition that litho printing proudly promotes, it is not without its set of contemporary difficulties. The most common issues include the high first setup expense, trouble in printing variable data, and environmental concerns because of chemical use. However, services are arising as technology develops. Digital litho printing permits cost-effective brief runs and very easy customization, attending to the issue of variable information. Environmentally-friendly inks and safer plate-making processes reduce ecological worries. In addition, developments in automation have actually lowered labor costs, even more democratizing the lithography process. Therefore, while there are difficulties, the litho printing market is proactively adjusting to fulfill them head-on, guaranteeing its importance in the future.

Conclusion

In conclusion, litho printing, with its rich history and clinical details, holds a substantial location in the print market. As the guide discloses, it's a synthesis of art and modern technology, with modern-day improvements ensuring its relevance. The sector encounters difficulties that require ingenious options, with a focus on automation and sustainability. The future of litho printing rests on its capability to adapt to click here to read these transforming demands, affirming its long-lasting worth in a progressing market.

Report this page